OUR COMMITMENT

Green & Lean Initiatives

Sustainable Manufacturing

US Aluminum Castings is proud to operate as an environmentally conscious company. As an ISO 14001 compliant facility, some of the environmental initiatives that US Aluminum Castings has implemented include:

- Wastewater Filtering

- Air Quality Protection

- Material Recycling

- Renewable Energy

At US Aluminum Castings, we believe wholeheartedly that we are stewards of this Earth.

This belief impacts our business strategy and long-term goals as we seek to reduce our environment impact through reduction, recycling, and renewability. We make every effort to capture and recycle those materials we do not sell as finished aluminum castings.

Renewable Energy

- Our facility runs on clean, green hydro-electric power generated 10 miles away at Chelan County’s Rocky Reach Dam.

- This renewable energy provides a low-impact, sustainable source of power, eliminating reliance on traditional melting fuels.

Air Quality Protection

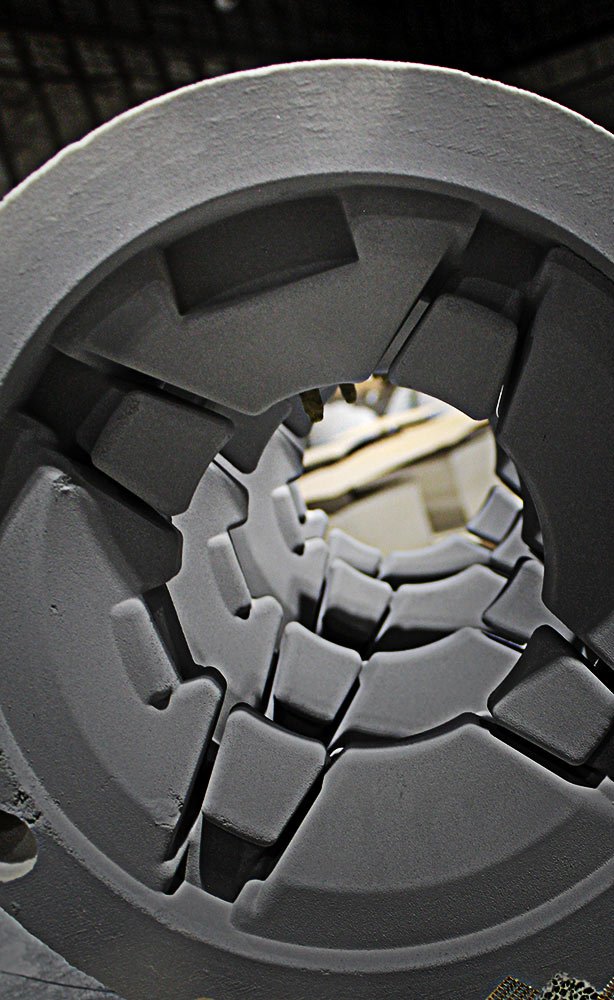

- Replaced our propane-fired melt furnace that burned over 300,000 gallons per year with a clean, electric-powered induction melting furnace.

- Worked with core resin suppliers to identify and sample “low smoke/low odor” resins to improve our indoor air quality and reduce our overall foundry emissions.

Wastewater Filtering

- Installed additional oil removal equipment to treat oily waste stream(s) to a greater extent than required by our wastewater permit issued by Washington State Dept. of Ecology

Material Recycling

- We recycle all scrap metals generated on site. These metals include aluminum, iron and steel. The aluminum is made up of grinding fines, impure oxides and dirt from our furnaces and chips from our machine shop. The iron and steel is waste from our maintenance activities and from obsolete or worn out molds.

- We capture and bundle our cardboard for recycling back into new cardboard.

- We recycle silver from our X-ray department.

- We receive most of our materials on wooden pallets. We recycle those pallets unfit for immediate re-use to pallet recyclers who rebuild the pallets to as-new condition.

Lean Manufacturing

US Aluminum Castings is proud to operate a fully LEAN foundry. What does that mean to you?

- Competitive Pricing

- Qaulity Product

- On-time Delivery

- USA-based Support

ECONOMY OF

SCALE

- We buy certified, 1,200 lb aluminum “T”s in railcar loads avoiding the wasteful handling and higher cost of the 40 lb. ingot.

- We melt & process using the lowest cost electricity in the US.

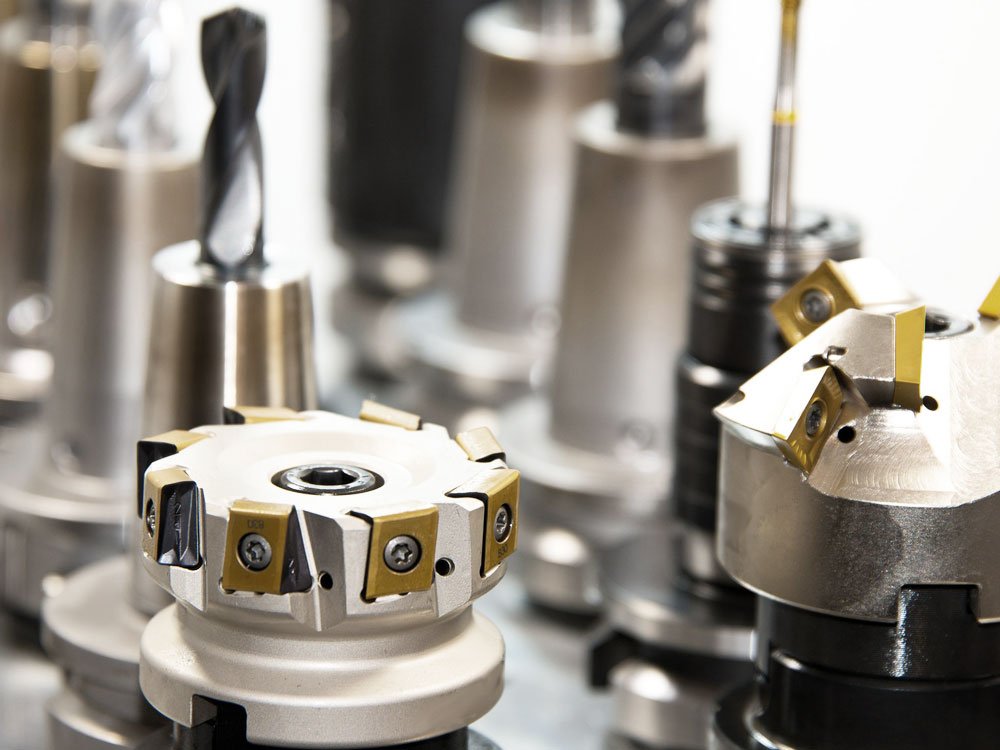

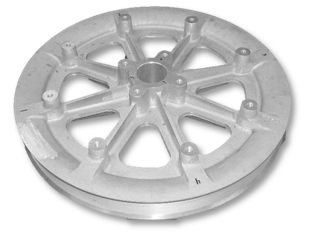

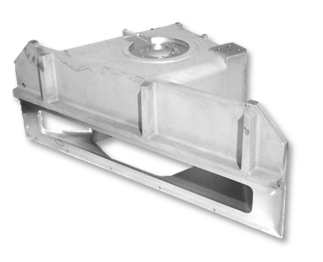

VALUE-ADDED SERVICES

- We melt, pour, heat treat, machine, inspect & powder coat under one roof avoiding the cost, delays and freight of outsourcing.

- We receive, process and invoice by EDI, web or e-mail, eliminating the delays and cost of handling paper

MANUFACTURING WITH INTENTION

- We are fully visual reducing the delays and missteps of uncertainty.

- We employ Kanban, Min-Max, and JIT manufacturing philosophies.

- Five S is implemented in every department, ensuring we maintain consistent quality.